Retention Devices

Retention Device for Ultra High Pressure Water Hoses for Cleaning Pipes

Higher safety requirements and the analysis of fatal accidents in the area of working with ultra high pressure water jets have initiated a change in requirements for the protective measures for those carrying out the work. As an example, mechanical safety gears for returning nozzles respectively pipe cleaning lances represent the state of the art and are therefore considered a mandatory safety measure.

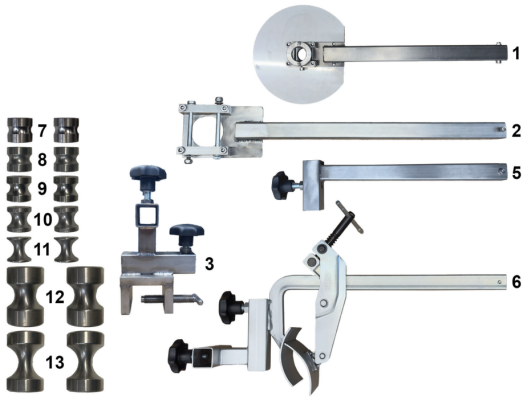

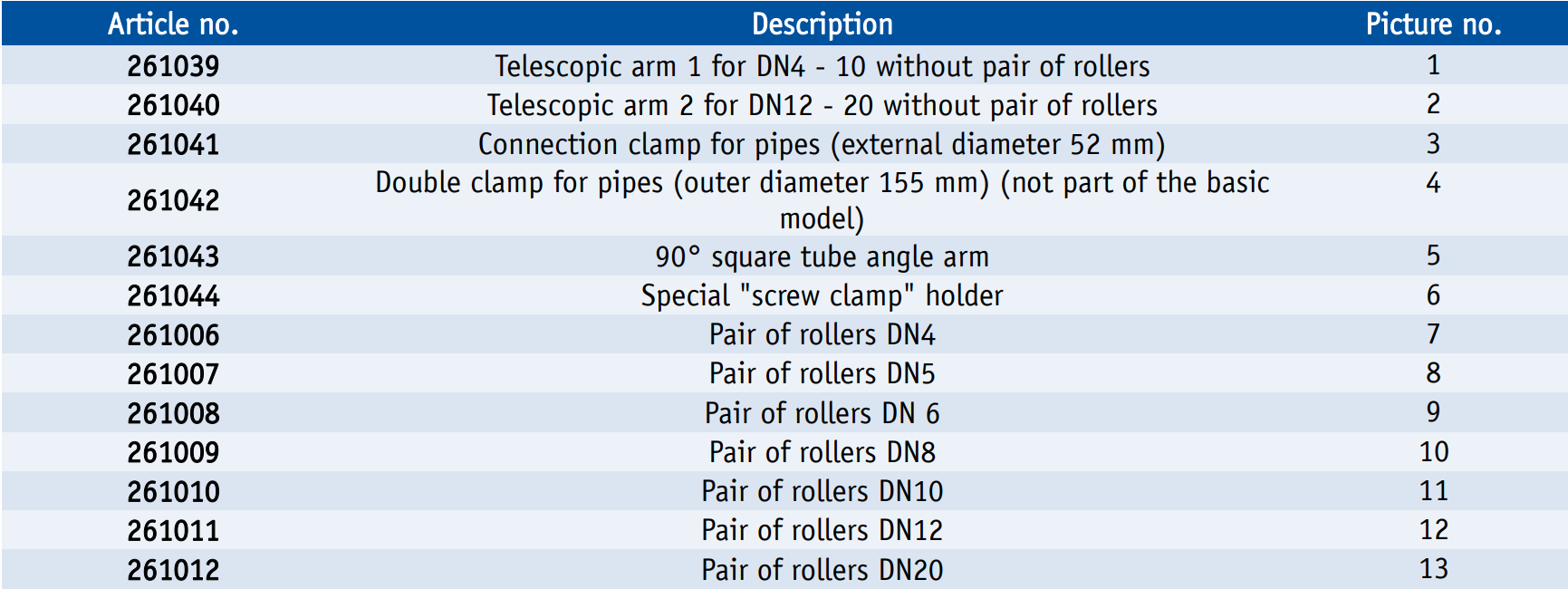

The retention device can be used by lance- and spiral hose workers mainly for cleaning in a broad variety of applications. Depending on pipe diameter and local conditions, the appropriate Fangkopf for the hoses DN 4 to 10, respectively DN 12 to 20 is positioned in front of the pipe with various clamping brackets and telescopic arms.

As proper clamping is a necessity, the pair of rollers must correspond to the respective hose diameter.

Due to the safety gear, nozzles and hoses remain fixed in work flow direction in case of a sudden aperture and can hence not endanger workers by whipping around or hitting them with an uncontrolled water jet.

The system was successfully presented to the work group “Flüssigkeitsstrahler” in the “Construction” professional association.

The basic model includes several clamping devices, and for DN4-10 respectively DN12-20 one telescopic arm each with roller holder.

The basic model does not contain a pair rollers. These must be ordered separately depending on the nominal hose size used.

All components are also available as individual parts, as replacements or repairs or for expansion.

Article no. 261005

Retention Device “Spiral Guide Arm” for Cleaning Heat Exchangers

The “Spiral Guide Arm” is a safety restraint device involved in the work with lance and spiral hoses and is primarily used for cleaning hear exchangers. Due to its broad range of clamping options, this restraint device can be used for other purposes, too. With its nozzle swivel and various telescopic arms, the junk basket can be brought into the desired positions easily, precisely and without great effort. Due to the safety gear, nozzles and hoses remain fixed in work flow direction in case of a sudden aperture and can hence not endanger workers by whipping around or hitting them with an uncontrolled water jet.

The application makes sense for heat exchangers with up to 2m in diameter and ultra high pressure water hoses DN 4-10 in particular.

For particular purposes, modified parts and special brackets can be ordered on request, for example for heat exchangers without a muff. Yet, these are not included in the basic model.

The basic model furthermore does not contain a pair of rollers. These must be ordered separately depending on the nominal hose size used. In case of repair or completion after loss, all the parts are moreover available as individual components.

As proper clamping is a necessity, the pair of rollers must correspond to the respective hose diameter.

Article-No.: 261004